【 pick to 】 tunnel monitoring purpose is through the tunnel convergence clearance and settlement observation, data analysis, the optimization of the tunnel construction plan and design, to ensure the safety of the reasonable interval and the supporting time, to ensure the safety of tunnel construction and after operation, while the work of tunnel monitoring measurement attached great importance to both at home and abroad, but the current monitoring level and informatization construction requirements also far.Based on 3 d laser scanning technology, this paper puts forward tunnel 3 d laser scanning measurement and data visualization processing technology, the engineering application and practice, the results show that the technique can be real-time, accurate, comprehensive space for tunnel deformation data, the tunnel construction the deformation analysis and the analysis, to conduct risk early warning and prediction of the tunnel construction guide tunnel informatization construction, has the important value of engineering application.

1 the introduction

The required measurement items of tunnel monitoring and measurement are often measured by level, steel scale, convergent meter and total station meter, etc. However, due to the low measurement accuracy, the level, steel scale and convergent meter are greatly affected by tunnel construction, which is easy to cause construction obstacles, and the heavy workload of data storage, transmission, processing and analysis is inconvenient for engineering application.The digital technology of total station has the advantages of high precision, convenient measurement, convenient data storage and transmission, and can be directly connected with the computer. In the friendly computer operating system, the monitoring data can be automatically transmitted, and the computer can be used for automatic analysis, processing and query, etc.With the continuous improvement of tunnel and underground engineering construction technology, information construction has become an inevitable trend of underground engineering development, and real-time monitoring of the project will play a more important role, and the requirements of monitoring and measurement are also getting higher and higher, which will inevitably promote the rapid development of real-time monitoring technology.Three-dimensional laser scanning technology http://www.longce.net can obtain spatial deformation data of the tunnel in a real-time, accurate and all-round manner, conduct deformation analysis and back analysis of tunnel construction, carry out risk early warning and forecast of tunnel construction, and guide tunnel information construction.

2. 3d laser scanning technology

Tunnel three-dimensional laser scanning visual monitoring technology using digital image processing and computer vision technology, will people use a variety of instruments of measurement data processing, transformation into people to intuitive, image understanding of image information, to help people find the data in the potential of all kinds of useful information, make people to be able to make a profound and comprehensive understanding of data obtained.

Tunnel three-dimensional laser scanning visual monitoring technology using whole section tunnel of 3 d laser radar scanner non-contact scanning measurement, monitoring stations layout into black and white reflective target or logo looked ball, active measurement instrument and store the tunnel to retrieve the item by the point cloud data, including entity in the same space coordinate system and description of target under the frame of reference entities spatial distribution and spectral characteristics of target surface mass point cloud data sets.The 3d solid model of tunnel space is obtained through point cloud splicing and filtering analysis, and the digital information processing and tunnel early warning and forecast are carried out to guide the construction and design of tunnel information.

3 points of cloud data acquisition

Tunnel project for a long and narrow structure, construction safety interval is commonly a few meters to dozens of meters, 3 d laser scanner to scan density is increased with the increase of the scanning distance decline, so within the tunnel limited tubular space, in order to ensure that there is plenty of point cloud data is used to extract the deformation information of the tunnel, usually the point cloud data obtained for each station in the effective scope of only a few tens of meters, this is the special tunnel under the special structure of the inevitable problems.When using 3D laser scanning technology to carry out tunnel monitoring and measurement, all data can only be collected by using sub-station scanning.In order to make a continuous and reliable monitoring data, scan data must have a certain contact ratio, which ensure the point cloud data splicing between every two stations in the process of public section, according to the tunnel cross-section size during monitoring, set up a station at regular intervals, used for splicing of locus of control can only be arranged in the connecting part between the two stations, between every two stations on the tunnel lining of uniform layout 5-6 reflective target, and lay on the ground three or four glance as a benchmark target joining together when will be the first stop, then each one station respectively with that of the adjacent station before joining together, station before and after the end to end.However, the measured point cloud data are in the independent coordinate system with each station as the origin, so it is necessary to splice the measured point cloud data when conducting the tunnel deformation analysis.

4 points of cloud data Mosaic

In the process of data acquisition in the tunnel monitoring section, a sub-station scan is required for the tunnel, and the subsequent data processing will inevitably involve the stitching of point cloud data. The stitching accuracy of point cloud data is an important prerequisite to ensure the calculation accuracy of a series of data in the later period, so the stitching errors should be minimized.

Point cloud data splicing is to unify the THREE-DIMENSIONAL coordinates of all points into the same coordinate system by calculating the conversion parameters between the coordinate systems where the cloud data of each two test stations are located.For scanned data, there is no distortion or scaling, only translation and rotation, or rigid body transformation.

The point cloud data splicing methods mainly include :(1) using special measuring instruments to realize the direct splicing of measurement data. This method is simple and fast, and does not require post-data splicing. The splicing accuracy depends on the measurement accuracy of hardware, but the system is usually complex, expensive, and cannot meet the measurement requirements of any visual Angle.(2) Based on the method of measuring surface adhesion markers, this method is used to calculate the splicing transformation parameters between two groups of point cloud data by attaching a sufficient number of markers. However, the resulting splicing accuracy is greatly affected by the number of markers, and is easily limited by the complex shape when determining the location of the markers;(3) according to the measurement of the point cloud data splicing algorithm after processing, the unified spliced into different coordinates of point cloud data under the same coordinate system, this method of splicing precision mainly depends on the stitching algorithm, categories can be roughly divided into the stitching algorithm based on point information, stitching algorithm based on geometry characteristic information, dynamic and stitching algorithm based on image stitching algorithm.

5. Engineering application and Practice

Treasure mountain tunnel is the key risk monitoring KunYu railway tunnel, the imports section shallow bias tunnel, the grade of surrounding rock for Ⅴ level, mainly strongly weathered marl, geological structure, the tunnel monitoring measurement using 3 d laser scanning tunnel monitoring technology for tunnel monitoring.

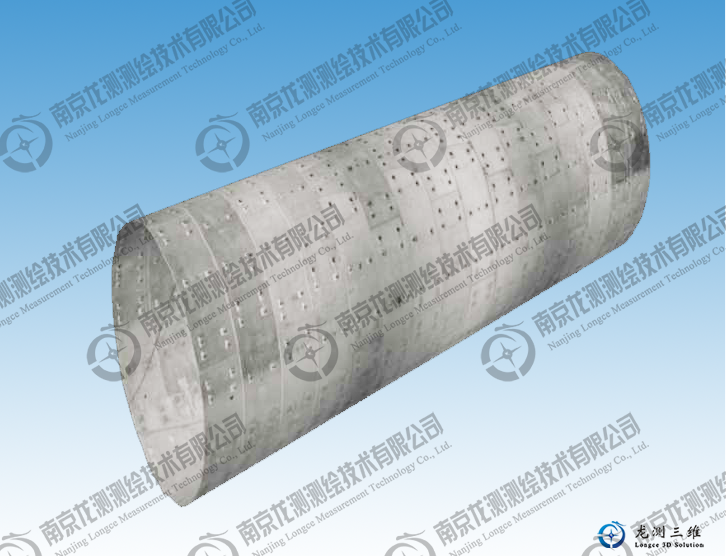

To timely grasp and convergence in the process of tunnel construction situation, analyze the tunnel monitoring data processing, using special analysis software of FARO SCENEhttp://www.longce.net/Download/ point cloud data processing and analysis, set up the tunnel three-dimensional entity model and analysis model, as shown in figure 1, the convergence and convergence analysis of tunnel clearance values as shown in figure 2, the Geomagic software can also browse and query the coordinates of an arbitrary point and other point cloud information, accurately grasp the tunnel clearance change rule,It provides a strong guarantee for the safe construction of the tunnel.

6 conclusions and Suggestions

Tunnel three-dimensional laser scanning real-time monitoring method is to use 3 d laser scanning system, comprehensive, high precision, high density acquisition mass entity point cloud data, and point cloud splicing, filtering processing such as tunnel real 3 d model and analysis results, generate different range profile and change analysis, can be used to analysis the clearance of the tunnel convergence and arch sedimentation, and early warning forecast, has reliable and real-time data processing and the advantages of full digital information, facilitate engineering informatization construction and management.

The engineering application shows that the 3d laser scanning monitoring method can acquire the dynamic data of tunnel construction quickly and in real time, master the dynamic change rule of tunnel, and guide the safe construction of tunnel informatization. It is the most ideal monitoring and measurement method at present and has achieved good application results.

Nanjing Long Measurement company has become a very professional 3d measurement solutions provider.At present, the company has set up r & D department, engineering department, technology Department, Marketing Department.The company's core technical personnel have become well-known experts in the industry, proficient in various laser scanner operations and data processing, can provide customers with hardware, software, rental, project cooperation and other complete 3D measurement solutions.

Address: Room 510, Zhixin Science and Technology Building, No. 15 xinghuo Road, Jiangbei New District, Nanjing

Sweep WeChat yards pay attention to us

Sweep WeChat yards pay attention to us

Quotation and presentation requestliuchunlei@longce.net

The mobile phone+86 13851969931

Nanjing Longce Measurement Technology Co., Ltd Address:No.15 Xinghuo Road, Jiangbei new district, Nanjing,China. ICP:苏ICP备20044645号-1